Introduction

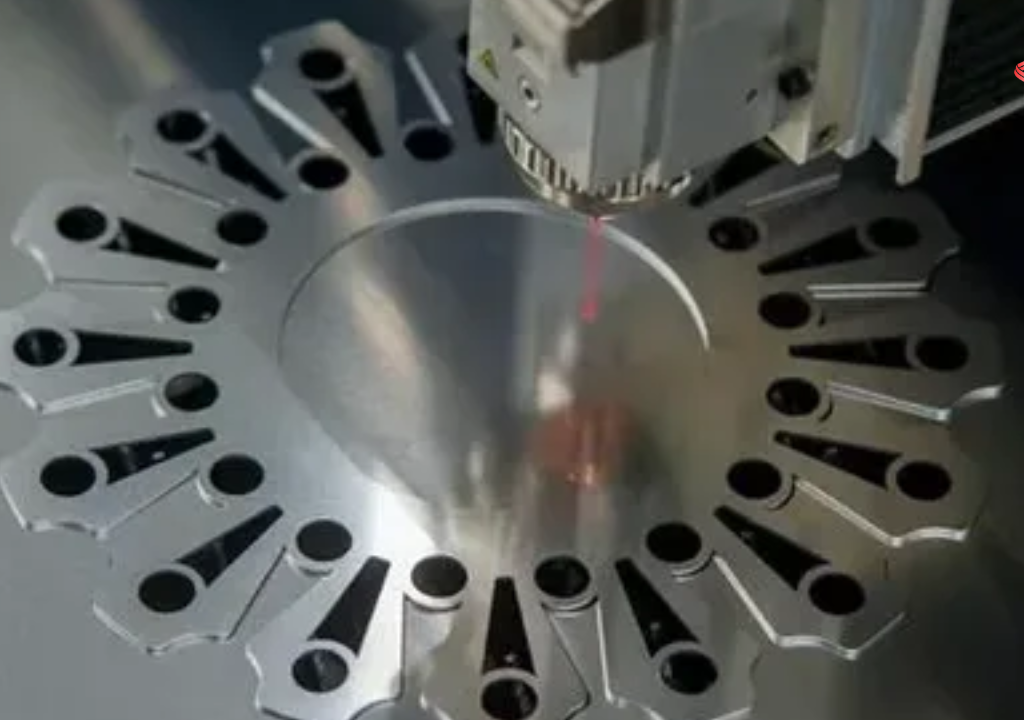

CNC laser cutting machine is a technological marvel that’s revolutionizing manufacturing, design, and creativity. Computer software controls the machines, which allow for complex designs with very few errors. They are commonly used in applications requiring precision and quality, such as in machine parts, decorative elements, and prototypes.

A modern manufacturing staple, CNC laser cutting machines provide precision, efficiency, and versatility. Because such wide applicability in industries cuts across metal fabrication, design, or electronics, you can assure that benefits from a CNC laser cutting machine in the end. Investing in such high technology would give you an uplift in your operations up several notches while assuring results of superior performance. CNC laser cutting machines are, therefore the ultimate solution in the pursuit of accuracy, speed, and economy desired in the modern manufacturing requirements.

Understanding CNC Laser Cutting Technology

It basically operates like a robot artist with surgical precision: it takes digital designs, and it makes real world realities out of them according to a computer programmed direction as small as the last milli meter. It is like having the smartest printer in town one which does not only print on paper but cuts through solid material as if it were a blade.

The Science Behind Laser Cutting

The laser beam in essence is a concentration of light and produces massive heat. When this beam focuses to a point, it makes it possible to melt, burn or vaporize material with exactness that could be likened to an actual lightsaber controlled like a computer!

Types of CNC Laser Cutting Machines

All laser cutters are not alike. Each has its superpower for different applications:

CO2 Laser Cutters

They are, in a way, a Swiss Army knife multitool dependable machines that cannot go wrong for the average consumer.

Fiber Laser Cutters

When it comes to metal, the heavyweight champions are fiber laser cutters. They cut through metal sheets as if a hot knife is slicing through butter, and thus they’re ideal for industrial manufacturing. Think of them as the bodybuilders of the laser cutting universe.

Nd:YAG Laser Cutters

They really shine at cutting reflective metals and ceramics. They are precision surgeons in the world of laser cutting, taking materials that would trouble other lasers and bringing it all to fruition.

Applications Across Industries

Manufacturing

Automotive parts or intricate electronic components are two examples where CNC laser cutters are unsung heroes of modern manufacturing. It is making complex parts with tolerances that a surgeon might feel jealous about.

Automotive

Car manufacturers rely on laser cutting for everything from body panels to intricate engine components. That’s like having a digital sculptor working on your most critical parts of your car.

Aerospace

In an industry where precision can mean life or death, aerospace engineers rely on CNC laser cutters to create components with a level of precision that amounts to the size of microscopic creatures.

Artistic and Design Fields

Artists and designers have found a new playground in laser cutting. Its creative possibilities range from making bespoke jewelry to architectural models.

Key Factors to Consider

Material Compatibility

Not all lasers are created equal. Some shine well with metals, while others with wood or plastics. Know your materials before buying.

Operating a CNC Laser Cutting Machine

Setup and Calibration

Accuracy is everything. Setting up the laser cutter correctly requires alignment, focusing the laser, and knowing what specific calibration requirements your machine needs. It is almost like finetuning a high performance sports car.

Maintenance and Troubleshooting

Regular Maintenance Tips

View your laser cutter like a powerful race car. Proper servicing prevents a breakdown and assures you optimal performance. That involves lens cleaning, alignment, and changing parts.

Frequent Problems and Solutions

This could range from misaligned lasers to a problem in the cooling system. It pays to learn how to troubleshoot such issues in advance so you save yourself money and time. Never fail to maintain a maintenance log and promptly solve issues.

Important Features to Look for in CNC Laser

- Cutting Machines

- Control systems:

- Automatically increase productivity. –

- Material compatibility:

- Multi material to operate on different projects. –

- Cooling system:

- Advanced to increase the lifetime of the machine. –

- Resolution:

- High to handle detailed projects.

Technological Inventions in CNC Laser Cutting

magine a technology that can slice through multiple materials in a single pass, or even selfdiagnose and correct its own malfunctions. That is the promise of the next generation of CNC laser cutting machines.

| Year | Milestone | Details |

|---|---|---|

| 1960s | Introduction of Laser Technology | Laser technology was first developed, paving the way for industrial applications. |

| 1970s | First Industrial Laser Cutting Machines | CO2 lasers were introduced for industrial cutting applications in metal fabrication. |

| 1980s | Integration with CNC Technology | CNC (Computer Numerical Control) was combined with lasers, enabling automated precision. |

| 1990s | Expansion to Non-Metal Materials | CNC laser cutters began being used for cutting plastics, wood, and other non-metal materials. |

| 2000s | Advances in Fiber Laser Technology | Fiber lasers became popular, offering higher efficiency and precision for diverse materials. |

| 2010s | AI and Software Integration | Machines became smarter, integrating AI for optimization and compatibility with advanced CAD software. |

| 2020s | Eco-Friendly Innovations | Focus shifted to energy-efficient and eco-friendly laser cutting technologies. |

| Present | Widespread Applications Across Industries | CNC laser cutters are now indispensable in industries like automotive, aerospace, and design. |

FAQs

1. What Material Thickness Can a CNC Laser Cutter Handle?

CNC laser cutters are highly versatile in material processing. Fiber laser systems can cut metallic materials up to 25mm thick, while CO2 laser cutters are best suited for nonmetallic materials, cutting sheets between 1012mm.

3. How Environmentally Friendly Are Modern CNC Laser Cutters?

Modern laser cutting technology is environmentally friendly. These machines are designed to be energy efficient, consuming less power than traditional cutting methods.

4. Are CNC Laser Cutters Suitable for Home or Small Workshop Use?

The market provides desktop and hobbylevel laser cutters for a much smaller operation. Such equipment is usually much less powerful compared to an industrial setup.

5. Professional CNC Laser Cutting Machine Price Range

Prices range highly from one CNC laser cutter to another depending on what its capabilities are and its application. For small business systems and workshop, entry price levels begin at $5,000

Future of CNC Laser Cutting Machine

The CNC laser cutting industry develops with the improvement in technology. Innovations like AI, enhanced software capabilities, and eco-friendly lasers make it more efficient and sustainable in these machines. The reason why industries require more and more precision and efficiency will always render CNC laser cutting machines indispensable.

Read more about our services at Red Craft Metal Industry